Wilujeng sumping di situs wéb kami!

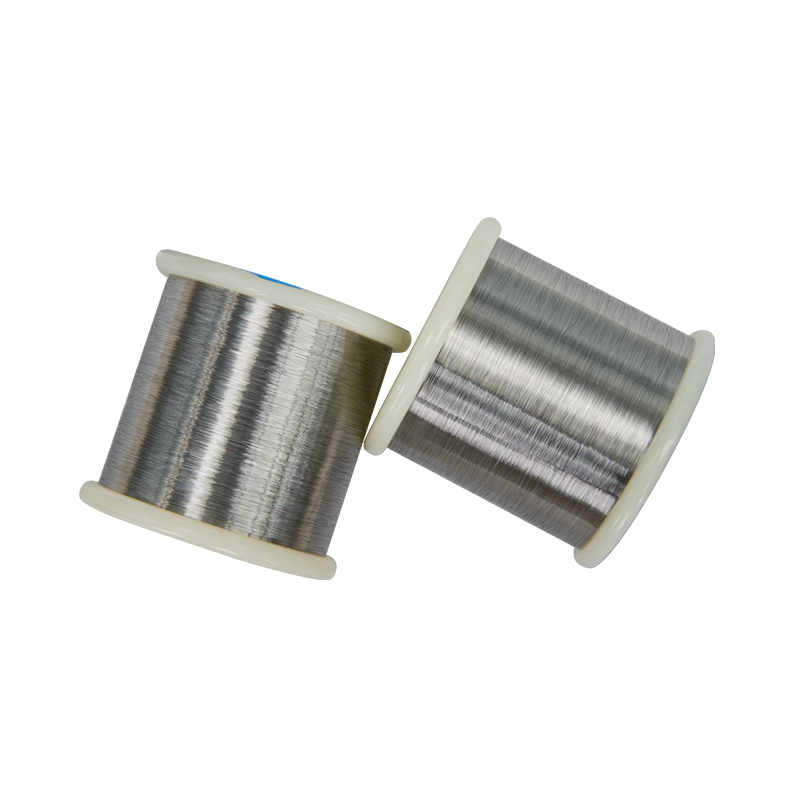

Kawat Paduan Segel Kaca Fenicr 4j6 Vacovit426

Komposisi Kimia dina %, Invar

| merek | Komposisi kimia | |||||||||

| Ni | Cr | Fe | C | P | Mn | B | Al | Si | S | |

| ≤ | ||||||||||

| 4j6 | 41.5~42.5 | 5.4~6.3 | Bal | 0.05 | 0.02 | 0.25 | - | 0.2 | 0.3 | 0.02 |

| 4j47 | 46.8~47.8 | 0.8~1.4 | Bal | 0.05 | 0.02 | 0.40 | - | - | 0.3 | 0.02 |

| 4j49 | 46.0~48.0 | 5.0~6.0 | Bal | 0.05 | 0.02 | 0.40 | 0.02 | - | 0.3 | 0.02 |

Konstanta fisik dasar sareng sipat mékanis tina paduan:

| merek | Kapadetan g / cm3 | résistansivitas | Titik Curie |

| 4j6 | 8.15 | 0.92 | 270 |

| 4j47 | 8.19 | 0.55 | 400 |

| 4j49 | 8.18 | 0.90 | 340 |

| Karakter ékspansi has (10 -6 / ºC) | ||||||||

| Rentang suhu | 20~100 | 20~200 | 20~300 | 20~400 | 20~500 | 20~400 | 20~550 | 20~600 |

| Koefisien ékspansi | 6.8 | 7.0 | 7.7 | 9.7 | 11.7 | 3.2 | 11.7 | 12.2 |

| Rupa-rupa | Jenis baja Spésifikasi | Presisi logam campuran | Paduan Résistansi pikeun pemanasan listrik | Paduan super | Kawat las | Tahan korosi logam campuran | |

| Batang | batang gulung panas | Φ8 ~ 38mm | sayogi | sayogi | sayogi | ||

| Batang anu ditarik tiis | ≤50mm | sayogi | sayogi | sayogi | |||

| Batang anu ditempa | Φ38 ~ 350mm | sayogi | sayogi | sayogi | |||

| Kawat | Kawat buleud | Φ0.3 ~ 8mm | sayogi | sayogi | sayogi | sayogi | sayogi |

| Kawat anu henteu bunderan | Negosiasi | sayogi | sayogi | sayogi | |||

| Strips | Ngagulung tiis | 0,15 ~ 4 × 200mm | sayogi | sayogi | sayogi | sayogi | |

| Gulungan panas | 4 ~ 22 × 200mm | sayogi | sayogi | sayogi | sayogi | ||

Tulis pesen anjeun di dieu sareng kirimkeun ka kami

Kategori produk

-

Telepon

-

Surélék

-

Whatsapp

-

WeChat

Judy

150 0000 2421

-

Luhur