Wilujeng sumping di situs wéb kami!

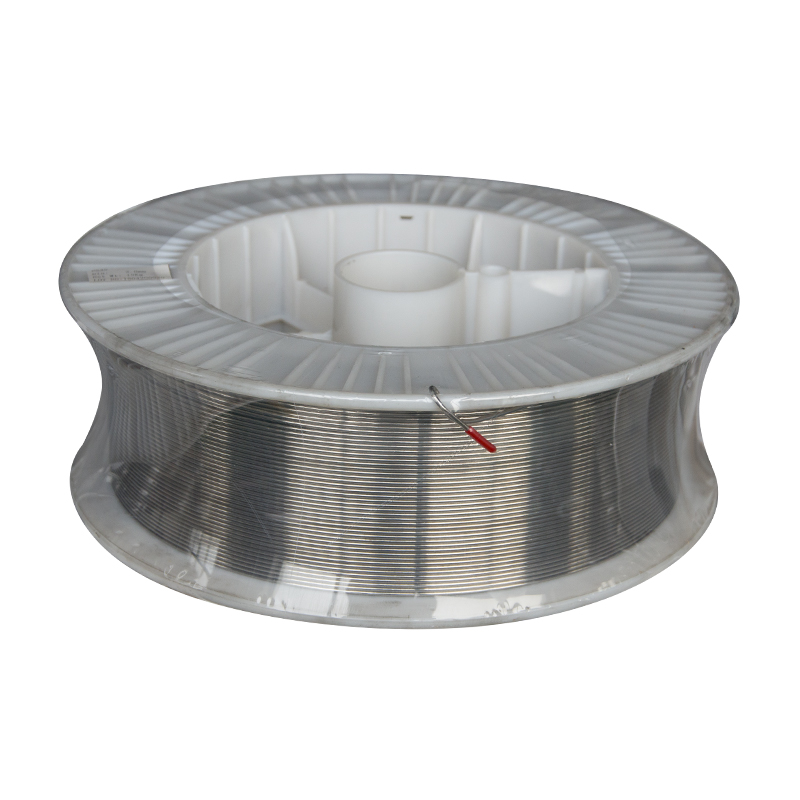

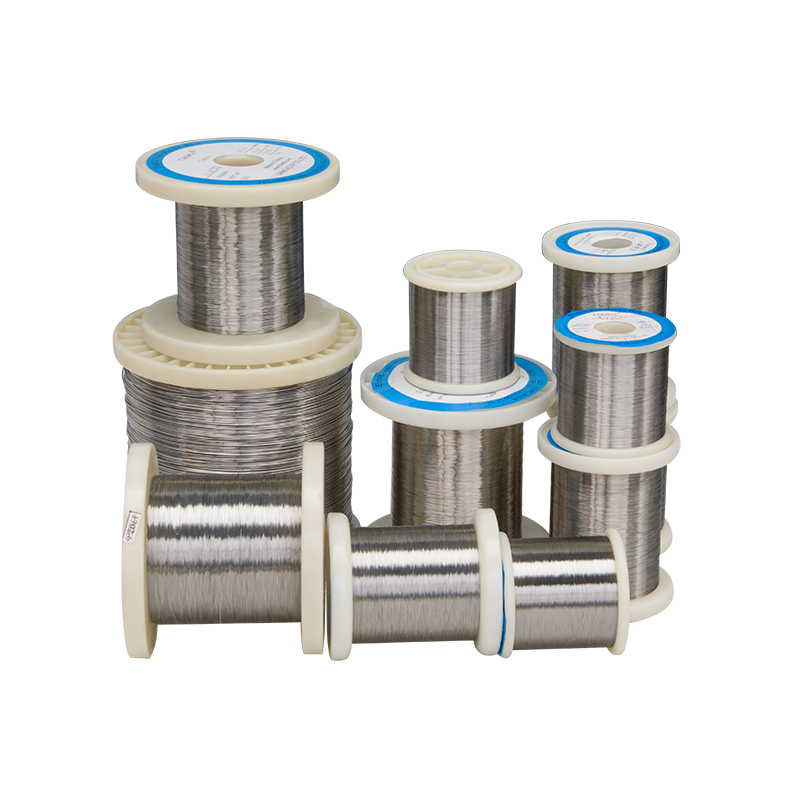

Kawat Paduan Tambaga Pérak AG-Cu

Bahan patri utama anu dianggo nyaéta AgCu7.5, AgCu25, AgCu28,AgCu55, jsb., sareng AgCu28 seueur dianggo. Éta gaduh konduktivitas, fluiditas sareng baseuh anu saé, sareng seueur dianggo dina industri vakum listrik. Kusabab résistansi anu handap kana beban jangka panjang dina suhu anu luhur, éta ngan cocog pikeun bagian patri anu suhu kerjana langkung handap tibatan 400ºC.

Dianggo salaku koin sareng hiasan. Paduan anu dianggo salaku koin nyaéta AgCu7.5, AgCu8,AgCu10, jsb.; logam campuran anu dianggo salaku hiasan nyaéta AgCu8.4, AgCu12.5, jsb.

Komposisi normal%

| Ag | Cu | Sn | Ni | Pb | Fe | Sb | Bi | |

| AgCu4 | 96+/-0.3 | 4+0.3/-0.5 | ≤0.005 | ≤0.05 | ≤0.002 | ≤0.002 | ||

| AgCu5 | 95+/-0.3 | 5+0.3/-0.5 | ≤0.005 | ≤0.05 | ≤0.002 | ≤0.002 | ||

| AgCu7.5 | 92.5+/-0.3 | 7.5+0.3/-0.5 | ≤0.005 | ≤0.1 | ≤0.002 | ≤0.002 | ||

| AgCu8.4 | 91.6+/-0.3 | 8.4+/-0.5 | ≤0.005 | ≤0.1 | ≤0.002 | ≤0.002 | ||

| AgCu10 | 90+/-0.3 | 10+/-0.5 | ≤0.005 | ≤0.2 | ≤0.002 | ≤0.002 | ||

| AgCu12.5 | 87.5+/-0.3 | 12.5+/-0.5 | ≤0.005 | ≤0.2 | ≤0.002 | ≤0.002 | ||

| AgCu20 | 80+/-0.3 | 20+/-0.5 | ≤0.005 | ≤0.2 | ≤0.002 | ≤0.002 | ||

| AgCu23 | 77+/-0.5 | 23+/-0.5 | ≤0.005 | ≤0.2 | ≤0.002 | ≤0.002 | ||

| AgCu25 | 75+/-0.5 | 25+/-0.5 | ≤0.005 | ≤0.2 | ≤0.002 | ≤0.002 | ||

| AgCu26 | 74+/-0.5 | 26+/-0.5 | ≤0.005 | ≤0.2 | ≤0.002 | ≤0.002 | ||

| AgCu28 | 72+/-0.5 | 28+/-0.5 | ≤0.005 | ≤0.2 | ≤0.002 | ≤0.002 | ||

| AgCu50 | 50+/-0.5 | 50+/-0.5 | ≤0.005 | ≤0.25 | ≤0.002 | ≤0.002 | ||

| AgCu99 | 1+/-0.2 | 99+0.2/-0.5 | ||||||

| AgCu18Ni2 | 80+/-0.5 | 18+/-0.5 | / | 2+/-0.3 |

Tulis pesen anjeun di dieu sareng kirimkeun ka kami

Kategori produk

-

Telepon

-

Surélék

-

Whatsapp

-

WeChat

Judy

150 0000 2421

-

Luhur