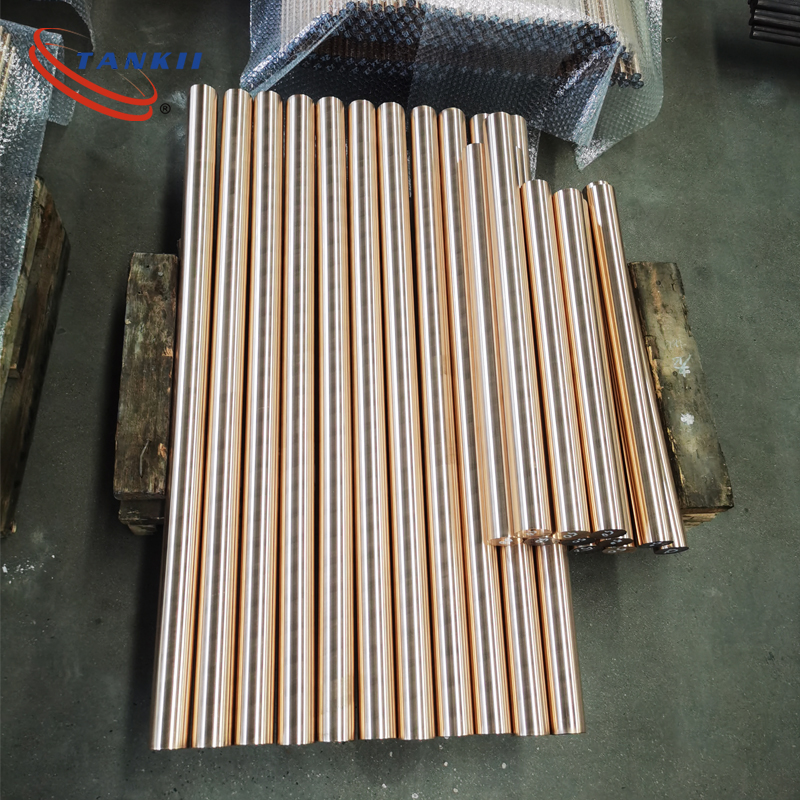

Kawat Inconel Alloy 625 718 600 Uns N06625 Kawat Halus/Filler/Welding

Inconel nyaéta kulawarga super alloy dumasar kromium nikel austenitik.

Paduan Inconel nyaéta bahan anu tahan korosi oksidasi anu cocog pikeun dianggo dina lingkungan ekstrim anu kakeunaan tekanan sareng

panas. Nalika dipanaskeun, Inconel ngabentuk lapisan oksida anu kuat, stabil, sareng pasif anu ngajaga permukaan tina serangan salajengna. Inconel nahan

kakuatan dina rentang suhu anu lega, pikaresepeun pikeun aplikasi suhu luhur dimana aluminium sareng baja bakal tunduk kana creak

salaku hasil tina lowongan kristal anu diinduksi sacara termal. Kakuatan suhu luhur Inconel dikembangkeun ku larutan padet

panguatan atanapi pengerasan présipitasi, gumantung kana paduanna.

Inconel 718 nyaéta paduan nikel-kromium-molibdenum anu dirancang pikeun tahan rupa-rupa lingkungan korosif anu parah, korosi liang sareng celah. Paduan baja nikel ieu ogé nunjukkeun sipat ngahasilkeun, tarik, sareng pecah anu luar biasa luhur dina suhu anu luhur. Paduan nikel ieu dianggo ti suhu kriogenik dugi ka layanan jangka panjang dina 1200° F. Salah sahiji ciri anu ngabédakeun tina komposisi Inconel 718 nyaéta panambahan niobium pikeun ngamungkinkeun pengerasan umur anu ngamungkinkeun annealing sareng las tanpa pengerasan spontan nalika pemanasan sareng pendinginan. Panambahan niobium bertindak sareng molibdenum pikeun ngakeueum matriks paduan sareng nyayogikeun kakuatan anu luhur tanpa perlakuan panas anu nguatkeun. Paduan nikel-kromium anu populér anu sanés dikeraskeun ku umur ngalangkungan panambahan aluminium sareng titanium. Paduan baja nikel ieu gampang didamel sareng tiasa dilas dina kaayaan dikeraskeun ku annealing atanapi présipitasi (umur). Superalloy ieu dianggo dina rupa-rupa industri sapertos aerospace, pamrosésan kimia, rékayasa kelautan, alat kontrol polusi, sareng réaktor nuklir.

Komponen suhu luhur, sapertos bilah turbin, baling-baling pituduh, cakram turbin, cakram kompresor tekanan luhur, manufaktur mesin sareng ruang durukan anu dianggo dina manufaktur turbin gas penerbangan, angkatan laut sareng industri.

| Barang | Inconel 600 | Inconel | Inconel 617 | Inconel | Inconel | Inconel | Inconel | |

| 601 | 690 | 718 | X750 | 825 | ||||

| C | ≤0.15 | ≤0.1 | 0.05-0.15 | ≤0.08 | ≤0.05 | ≤0.08 | ≤0.08 | ≤0.05 |

| Mn | ≤1 | ≤1.5 | ≤0.5 | ≤0.35 | ≤0.5 | ≤0.35 | ≤1 | ≤1 |

| Fe | 6~10 | istirahat | ≤3 | istirahat | 7~11 | istirahat | 5~9 | ≥22 |

| P | ≤0.015 | ≤0.02 | ≤0.015 | – | – | – | – | – |

| S | ≤0.015 | ≤0.015 | ≤0.015 | ≤0.015 | ≤0.015 | ≤0.01 | ≤0.01 | ≤0.03 |

| Si | ≤0.5 | ≤0.5 | ≤0.5 | ≤0.35 | ≤0.5 | ≤0.35 | ≤0.5 | ≤0.5 |

| Cu | ≤0.5 | ≤1 | – | ≤0.3 | ≤0.5 | ≤0.3 | ≤0.5 | 1.5-3 |

| Ni | ≥7.2 | 58-63 | ≥44.5 | 50-55 | ≥58 | 50-55 | ≥70 | 38-46 |

| Co | – | – | 10~15 | ≤10 | – | ≤1 | ≤1 | – |

| Al | – | 1-1.7 | 0.8-1.5 | ≤0.8 | – | 0.2-0.8 | 0.4-1 | ≤0.2 |

| Ti | – | – | ≤0.6 | ≤1.15 | – | – | 2.25-2.75 | 0.6-1.2 |

| Cr | 14-17 | 21-25 | 20-24 | 17-21 | 27-31 | 17-21 | 14-17 | 19.5-23.5 |

| Nb+Ta | – | – | – | 4.75-5.5 | – | 4.75-5.5 | 0.7-1.2 | – |

| Mo | – | – | 8~10 | 2.8-3.3 | – | 2.8-3.3 | – | 2.5-3.5 |

| B | – | – | ≤0.006 | – | – | – | – | – |

Kategori produk

-

Telepon

-

Surélék

-

Whatsapp

-

WeChat

Judy

150 0000 2421

-

Luhur