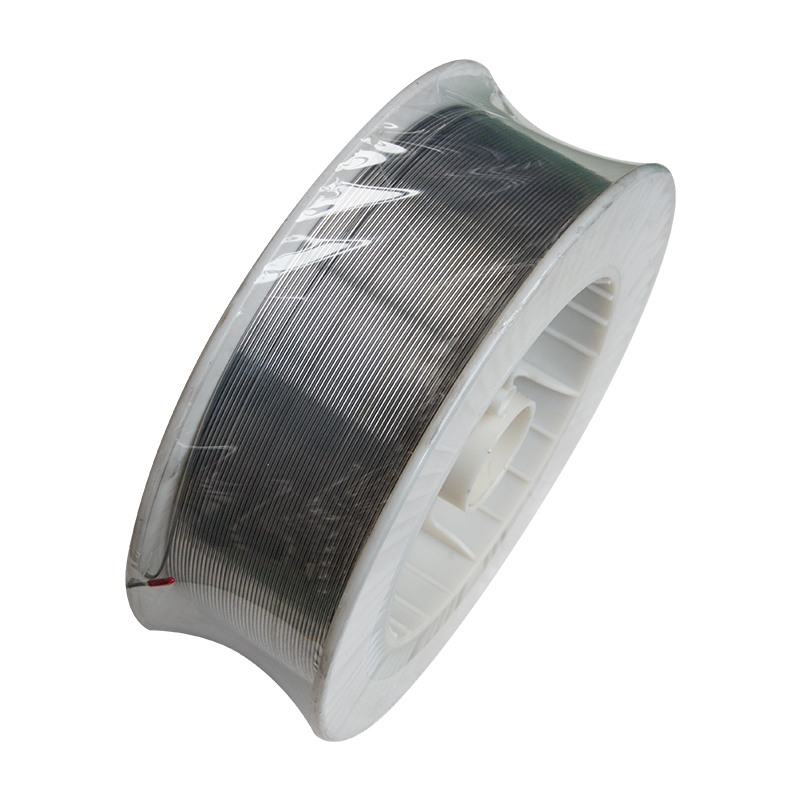

Vacon 12 Fe-Ni-Co Kaca Sealing Alloy Kawat Kovar Alloy Kawat

Vacon 12Kawat Paduan Segel Kaca Fe-Ni-CoKovarKawat Paduan

(Ngaran Umum:Kovar, Nilo K, KV-1, Dilver Po, Vacon 12)

Spésifikasi:Lambaran/Pelat, Batang/Rod/Kawat/Kumparan, Kapiler/Pipa/Tabung

Rentang Ukuran:

—*Lambaran_Kandelna 0.1mm ~ 40.0mm, lébar: ≤300mm, Kaayaan: digulung tiis (panas), caang, caang dipanaskeun

—*BuleudDiaméter Kawat 0.1mm~Diaméter 5.0mm, Kaayaan: ditarik tiis, caang, caang dipanaskeun

—*Kawat DatarDiaméter 0.5mm~Diaméter 5.0mm, panjangna: ≤1000mm, Kaayaan: digulung rata, dipanaskeun caang

—*BarDiaméter 5.0mm ~ Diaméter 8.0mm, panjangna: ≤2000mm, Kaayaan: ditarik tiis, caang, caang dipanaskeun

Diaméter 8.0mm~Diaméter 32.0mm, panjangna: ≤2500mm, Kaayaan: digulung panas, caang, dipanaskeun caang

Diaméter 32.0mm~Diaméter 180.0mm, panjangna: ≤1300mm, Kaayaan: ditempa panas, dikupas, dibalikkeun, diubaran panas

—*Kapiler_OD 8.0mm~1.0mm, ID 0.1mm~8.0mm, panjangna: ≤2500mm, Kaayaan: ditarik tiis, caang, caang dipanaskeun

—*Pipa_OD 120mm ~ 8.0mm, ID 8.0mm ~ 129mm, panjang: ≤4000mm, Kaayaan: ditarik tiis, caang, caang dipanaskeun

Aplikasi:

Utamana dianggo dina komponén vakum listrik sareng kontrol émisi, tabung kejut, tabung panyala, magnetron kaca, transistor, colokan segel, relay, kabel sirkuit terpadu, chassis, braket sareng segel wadah anu sanés.

Komposisi normal%

| Ni | 28.5~29.5 | Fe | Bal. | Co | 16.8~17.8 | Si | ≤0.3 |

| Mo | ≤0.2 | Cu | ≤0.2 | Cr | ≤0.2 | Mn | ≤0.5 |

| C | ≤0.03 | P | ≤0.02 | S | ≤0.02 |

Kakuatan Tarik, MPa

| Kode kaayaan | Kaayaan | Kawat | Jalur |

| R | Lemes | ≤585 | ≤570 |

| 1/4I | 1/4 Teuas | 585~725 | 520~630 |

| 1/2I | 1/2 Teuas | 655~795 | 590~700 |

| 3/4I | 3/4 Teuas | 725~860 | 600~770 |

| I | Teuas | ≥850 | ≥700 |

Sipat Fisik Khas

| Kapadetan (g/cm3) | 8.2 |

| Résistansi listrik dina 20ºC (Ωmm2/m) | 0.48 |

| Faktor suhu résistivitas(20ºC~100ºC)X10-5/ºC | 3.7~3.9 |

| Titik Curie Tc/ºC | 430 |

| Modulus Élastis, E/ IPK | 138 |

Koefisien ékspansi

| θ/ºC | α1/10-6ºC-1 | θ/ºC | α1/10-6ºC-1 |

| 20~60 | 7.8 | 20~500 | 6.2 |

| 20~100 | 6.4 | 20~550 | 7.1 |

| 20~200 | 5.9 | 20~600 | 7.8 |

| 20~300 | 5.3 | 20~700 | 9.2 |

| 20~400 | 5.1 | 20~800 | 10.2 |

| 20~450 | 5.3 | 20~900 | 11.4 |

Konduktivitas termal

| θ/ºC | 100 | 200 | 300 | 400 | 500 |

| λ/ W/(m*ºC) | 20.6 | 21.5 | 22.7 | 23.7 | 25.4 |

| Prosés perlakuan panas | |

| Ngaleueut pikeun ngurangan setrés | Dipanaskeun nepi ka 470~540ºC teras tahan 1~2 jam. Tiiskeun heula |

| annealing | Dina vakum dipanaskeun nepi ka 750 ~ 900ºC |

| Waktos nahan | 14 menit ~ 1 jam. |

| Laju pendinginan | Teu leuwih ti 10 ºC/mnt didinginkan nepi ka 200 ºC |

Kategori produk

-

Telepon

-

Surélék

-

Whatsapp

-

WeChat

Judy

150 0000 2421

-

Luhur