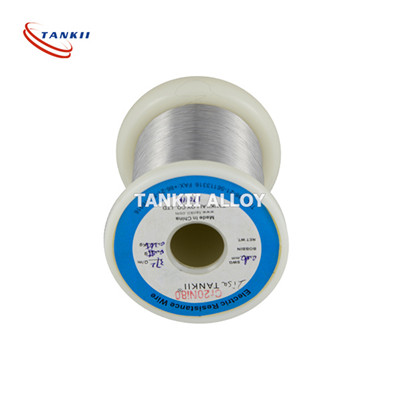

Tambaga Nikel Alloy Kawat

Panjelasan Produk

Paduan Nikel Tambaga (CuNi) nyaéta bahan résistansi sedeng dugi ka handap, biasana dianggo dina aplikasi kalayan suhu operasi maksimal dugi ka 400 ° C (750 ° F).

Kalawan koefisien hawa low lalawanan listrik, résistansi, sahingga kinerja, konsisten paduli hawa. Tambaga nikel alloy mechanically boast ductility alus, gampang soldered na dilas, kitu ogé mibanda résistansi korosi beredar. alloy ieu ilaharna dipaké dina aplikasi ayeuna tinggi merlukeun tingkat precision tinggi.

Tambaga-base lalawanan panas kawat résistansi low, boga résistansi korosi alus, sipat las sarta sipat machinable, cocog pikeun di relay overload termal, a-tegangan low circuit breakers, sarta panerapan listrik low-tegangan sejen tur panerapan rumah tangga jeung panerapan listrik lianna manufaktur elemen pemanasan, sarta mangrupa bahan penting dina produksi kabel pemanasan.

| Kodeu | Résistansi | Ma.Gawé Watek | Temp.Coeffi. Tina Résistansi | EMF Ngalawan Tambaga (0 ~ 100 ℃) | Komposisi Kimia (%) | Mékanis, Pasipatan | |||||

| Mn | Ni | Cu | Kakuatan Tensile (N/mm2) | Elongation% (Kirang ti) | |||||||

| Diaméter <=1.0mm | Diaméter> = 1.0mm | ||||||||||

| NC003 | CuNi1 | 0.03 | 200 | <100 | -8 | - | 1 | Istirahat | 210 | 18 | 25 |

| NC005 | CuNi2 | 0.05 | 200 | <120 | -12 | - | 2 | Istirahat | 220 | 18 | 25 |

| NC010 | CuNi6 | 0.10 | 220 | <60 | -18 | - | 6 | Istirahat | 250 | 18 | 25 |

| NC012 | CuNi8 | 0.12 | 250 | <57 | -22 | - | 8 | Istirahat | 270 | 18 | 25 |

| NC015 | CuNi10 | 0.15 | 250 | <50 | -25 | - | 10 | Istirahat | 290 | 20 | 25 |

| NC020 | CuNi14 | 0.20 | 250 | <38 | -28 | 0.3 | 14.2 | Istirahat | 310 | 20 | 25 |

| NC025 | CuNi19 | 0.25 | 300 | <25 | -32 | 0.5 | 19 | Istirahat | 340 | 20 | 25 |

| NC030 | CuNi23 | 0.30 | 300 | <16 | -34 | 0.5 | 23 | Istirahat | 350 | 20 | 25 |

| NC035 | CuNi30 | 0.35 | 300 | <10 | -37 | 1.0 | 30 | Istirahat | 400 | 20 | 25 |

| NC040 | CuNi34 | 0.40 | 350 | 0 | -39 | 1.0 | 34 | Istirahat | 400 | 20 | 25 |

| NC050 | CuNi44 | 0.50 | 400 | <-6 | -43 | 1.0 | 34 | Istirahat | 420 | 20 | 25 |

| Paduan | DN-Nami Dagang | Bahan-No. | UNS-No. | Spésifikasi ASTM | Spésifikasi DIN |

| CuNi1 | CuNi1 | ||||

| CuNi2 | CuNi2 | 2.0802 | C70200 | ASTM B267 | DIN 17471 |

| CuNi6 | CuNi6 | 2.0807 | C70500 | ASTM B267 | DIN 17471 |

| CuNi10 | CuNi10 | 2.0811 | C70700 | ASTM B267 | DIN 17471 |

| CuNi10Fe1Mn | CuNi10Fe1Mn | (2.0872) / (CW352H) | C70600 | ASTM B151 | |

| CuNi15 | CuNi15 | ||||

| CuNi23Mn | CuNi23Mn | 2.0881 | C71100 | ASTM B267 | DIN 17471 |

| CuNi30Mn | CuNi30Mn | 2.0890 | |||

| CuNi30Mn1Fe | CuNi30Mn1Fe | (2.0882) / (CW354H) | C71500 | ASTM B151 | |

| CuNi44Mn1 | Vernicon | 2.0842 | DIN 17471 |

294: Ngaran umum:

Alloy294, Cuprothal294, Nico, MWS-294, Cupron, Copel, Alloy45, Cu-Ni102, Cu-Ni44, Cuprothal, Cupron, Copel, Neutrology, Advance, Konstantan

A30: Ngaran umum:

Alloy 30, MWS-30, Cuprothal 5, Cu-Ni 23, Alloy 260, Cuprothal 30 HAI-30, Cu-Ni2, Alloy 230, Nikel Alloy 30

A90: Ngaran umum:

Alloy 95, 90 Alloy, MWS-90, Cu-Ni 10, Cuprothal 15, Cu-Ni 10, Alloy 320 Alloy 90, Alloy 290, #95 Alloy, Cuprothal 90, HAI-90, Alloy 260, Nikel Alloy 90

A180: Ngaran umum:

Alloy 180, 180 Alloy, MWS-180, Cuprothal 30, Midohm, Cu-Ni 23, Nikel Alloy 180

Kategori produk

-

Telepon

-

Surélék

-

Whatsapp

-

WeChat

Judy

150 0000 2421

-

Puncak